Product Description

Gorilla Foam Seal Insulating Foam Sealant is a Multi-Purpose Formula that expands to fill gaps & cracks up to 1 in. It does not cause bowing making it great for windows & doors, and can be used in both indoor & outdoor applications. This formula has maximum durability with high flexibility, strong adhesion, and UV resistance* that provides protection for minimal outdoor degradation. Dispensed product is tack free in 8-12 minutes and can be trimmed in 45 minutes. Use to seal out air, moisture, pests, and insects. Can be used on wood, metal, glass, masonry, plumbing, HVAC, electrical**, basements, crawlspaces, attics, ceilings, skylights, and more!

*Exposure to sunlight causes discoloration. For outdoor use, coat with exterior paint. Not for filling closed cavities or voids. Not for use on or within heat-emitting devices or in areas that require fireproof and/or fire stopping materials.

**Do not use inside electrical outlets or junction boxes. Not for filling closed cavities or voids. Not for use on or within heat-emitting devices or in areas that require fireproof and/or fire-stopping materials.

Features & Benefits

- SEALS OUT AIR, MOISTURE, PESTS & INSECTS.

- REDUCES DRAFTS FOR ENERGY EFFICIENCY.

- UL CLASSIFIED (UL 723).

- MAXIMUM DURABILITY: High Density, Flexible, Strong Adhesion & UV Resistant.

- SANDABLE & PAINTABLE.

- GREAT FOR: Filling Gaps & Cracks; Insulating Windows & Doors; Sealing out Air, Moisture, Pests, & Insects; and Reducing Drafts for Energy Efficiency.

Application Instructions

Always wear eye protection, gloves, and proper work clothing when using foam. Cured foam is difficult to remove from skin, clothing, and other substrates.

Prep areas by thoroughly cleaning.

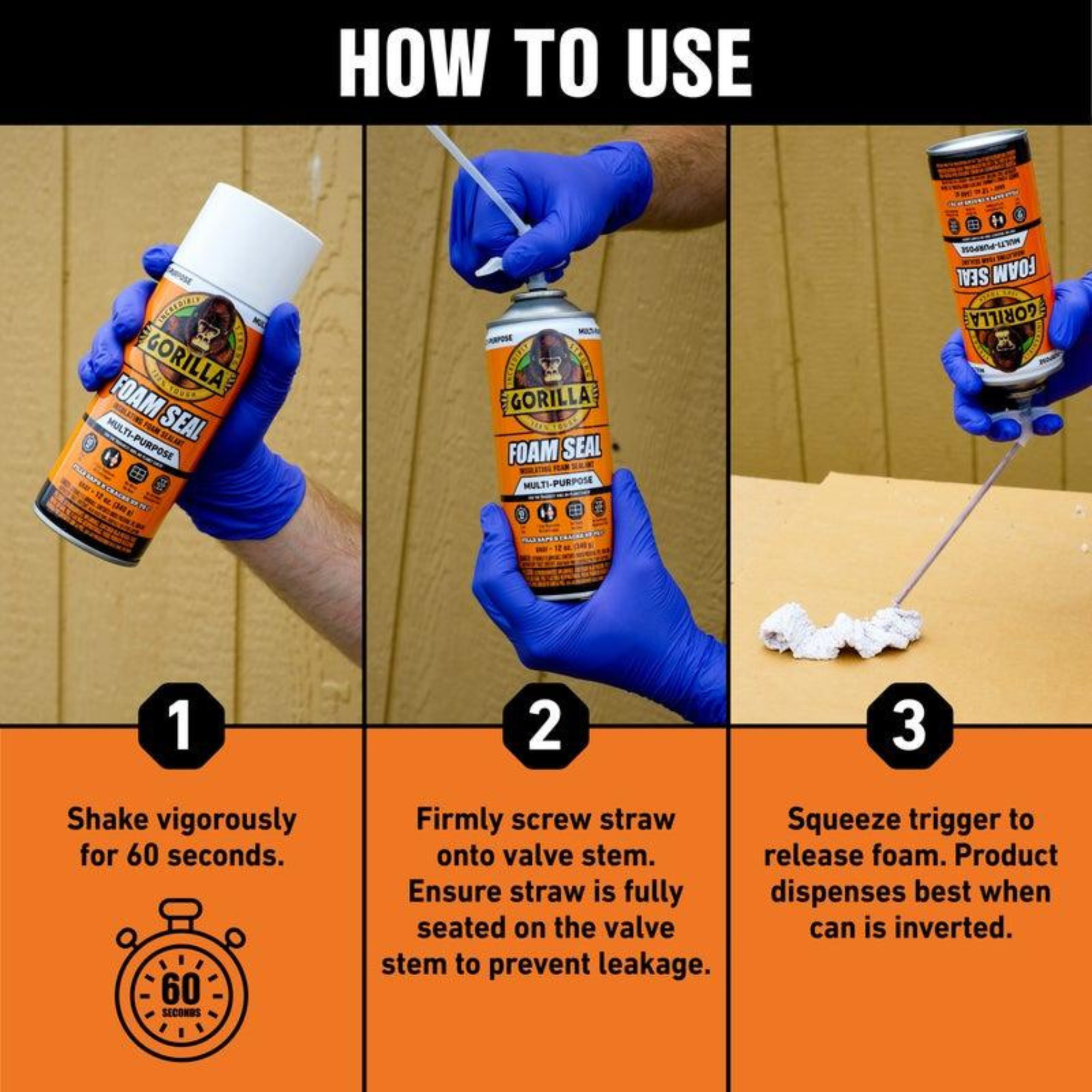

Shake can for 60 seconds and immediately attach the straw applicator.

Test dispense pressure/foam expansion in an area separate from your project.

When applying foam, only fill crevice up to 40% as foam will continue to expand after dispensed.

Foam will be tack free in 8-12 minutes, can be cut after 45 minutes, and fully cures in 8 hours.

Once cured, trim excess foam. Cured foam can be trimmed, sanded, and painted. Do not leave cured foam in direct sunlight without painting.

Note: Before use store upright in a cool, dry place. After use product may continue to expand out of the straw. Not intended for reuse. Cure time may vary depending on temperature and humidity.

Technical Information

Gorilla Insulating Foam Sealant

- Standards Met: Meets AAMA 812-19, UL Classified

- Service/Operating Temperature: -58°F to 194°F

- Application Temperature: 50°F to 77°F

- Weight: 1 pound 1 ounce

- Outdoor: Yes. Exposure to sunlight causes discoloration. Do not leave cured foam in direct sunlight without painting.

- Moisture Resistant: Yes

- Paintable: Yes

- Sandable: Yes

- Stainable: No

- Cured Color: Gray

- Gap Filling: Yes. Fills Gaps & Cracks up to 1 in.

- Storage Tips: Before use store upright in a cool, dry place. After use product may continue to expand out of the straw. Not intended for reuse. Cure time may vary depending on temperature and humidity.

- Country of Origin: Estonia

Note: Specifications are those given by manufacturers and are not tested for accuracy.